6 October 2023

MRP invests in the latest state-of-the-art Laminator

In-line with our continued investment plan, we are excited to announce the recent installation of our Fengchi High-Speed Laminator - GW-1450L, which replaces our previous Lamina Laminator. This machine offers greater versatility, productivity and efficiency. It is specifically designed for sheet-to-sheet mounting of paper to board and board to board, both solid and corrugated.

With a running speed of over 10,000 sheets per hour, this laminator has the ability to mount two sheets of board together in various thicknesses as well as paper to board. This machine can also mount various substrates to open or closed-faced corrugated board. The laminator has full servo control with edge-to-edge registration accuracy and automatic feeding.

The machine also comes with a 'Flip Flop Stacker' that automatically turns the sheets to prevent curling, with no effect on running speed. Previously, this process was done manually and adversely affected the machine output.

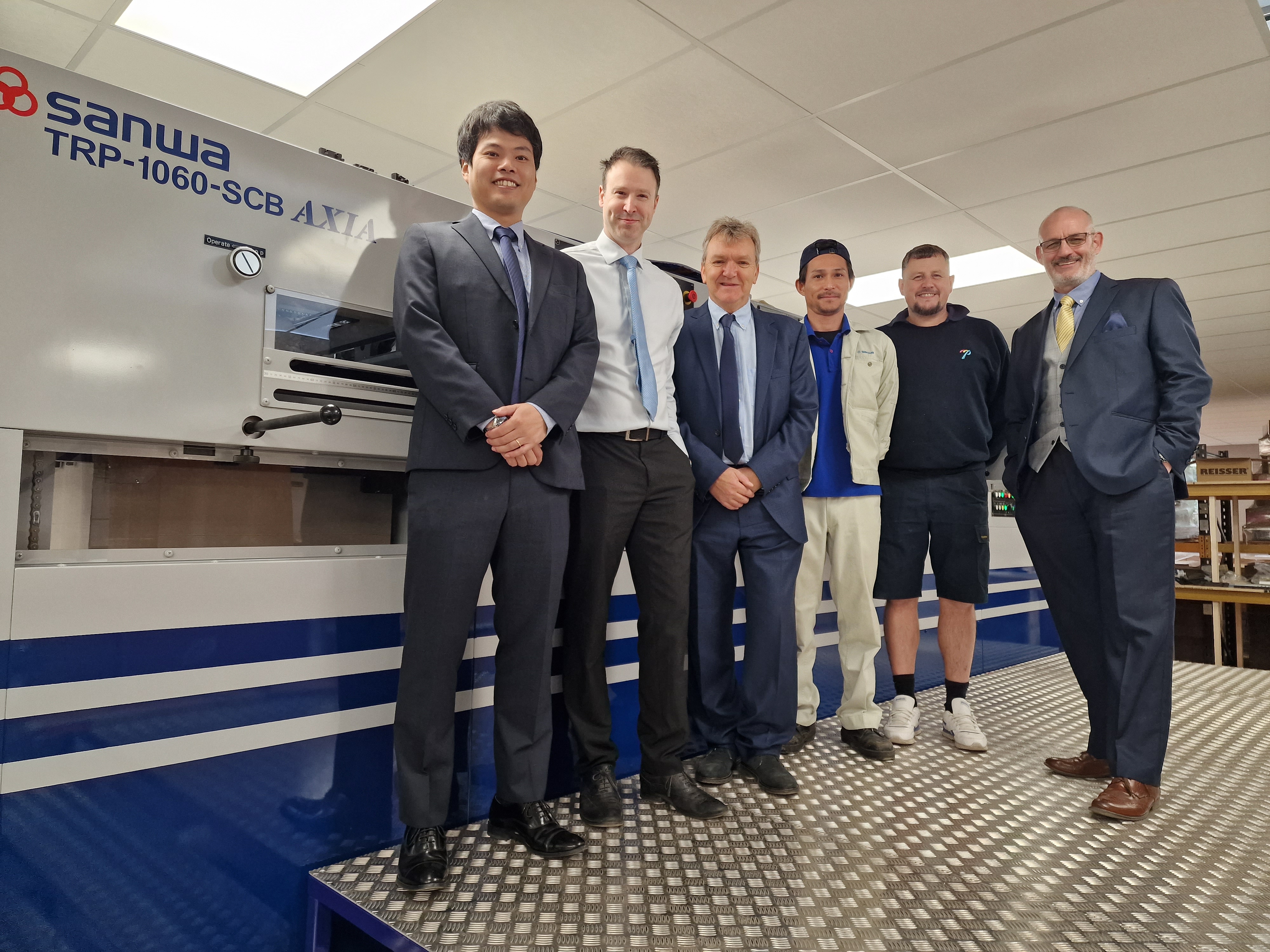

Our new is a Sanwa 1060 S.C.B. Axia is now fully operational as well - giving us far greater die cutting capacity within our packaging division and this will run alongside our existing Sanwa die cutter.

The Axia is designed for die cutting and blanking both solid and corrugated boards and has a running speed of 8,000 sheets per hour. It also has edge-to-edge registration accuracy and automatic feeding.

We are also waiting delivery on two advanced packers for the gluing machines.

Kate Tew ”We believe the addition of both of these machines will offer far greater options to our existing clients, improve turnaround times and also open up new markets. Going forward, we foresee huge growth in this area with our clients looking for environmentally friendly options and moving away from plastic.”

All CAD design, printing, mounting, die-cutting, and gluing take place at our Nottingham site. We also offer full self-adhesive label and ribbon printing, maintaining colour consistency across all your printed products.

Midland Regional Printers are committed to quality and service, holding both the ISO 9001 and 14001 accreditations, as well as FSC certified. We also plant trees for every order received. We take pride in the company's structure, staying up-to-date with technology, and our fully integrated plant, which enables us to be versatile and meet customer requirements.

Mounter Photo left to right: Michael Tew, Stephen Bates, Kate Tew

Sanwa Photo left to right: Yuta Matsumoto (Sanwa), Michael Tew (MRP), Neil Gaskin (Sanwa), Yusuke Nakano (Sanwa), Jay Dooley (MRP), Stephen Bates (Managing Director – MRP).

Sexual Harassment – 'Preventative Duty’

Sexual Harassment – 'Preventative Duty’

25 November 2024

The Worker Protection Act 2023 (Amendment of the Equality Act 2010), is UK legislation designed to enhance protections against workplace sexual harassment.

INTERGRAF OPENS APPLICATIONS FOR THE 2025 YOUNG TALENT AWARD

INTERGRAF OPENS APPLICATIONS FOR THE 2025 YOUNG TALENT AWARD

4 December 2024

Intergraf is pleased to announce that applications are now open for the 2025 Young Talent Award, an initiative designed to inspire and shape the future of the print industry. This year, the Award invites young talent to explore how print companies can effectively attract and engage younger generations to pursue careers in the print industry.